Off Grid IIoT Solar System

Tamimi February 01, 2014 [Professional] #Automation #Solar Cells #PV #Engineering #IIoT

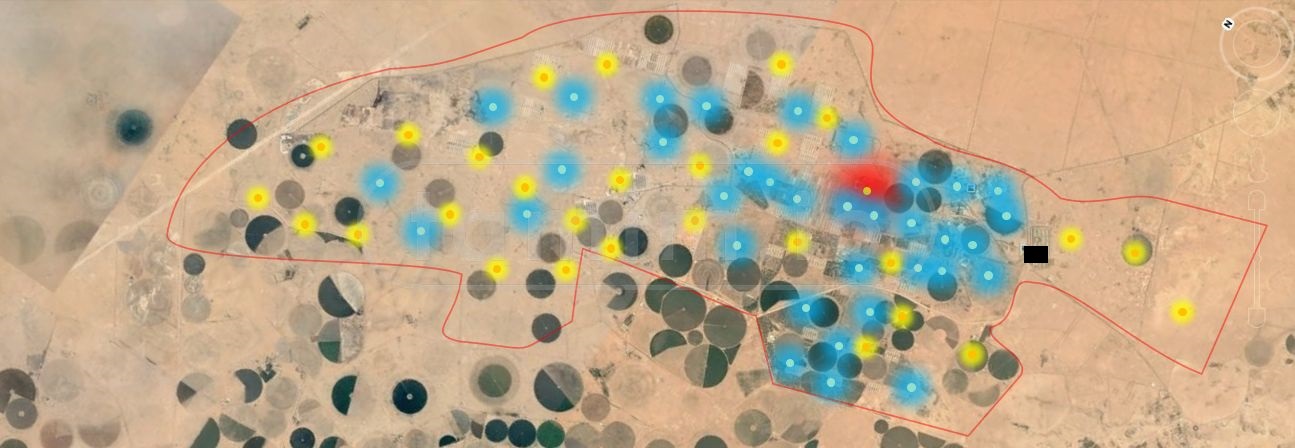

Img1: One of the solar powered RTUs

Introduction

While the Industrial Automation SCADA System roject was being installed, another smaller project came up after a feasibility study showed that some of the RTUs panels would be better off powered by an off-grid solar system, so this project was born!

Scope

Img2: Yellow dots are the solar powered panels.

Out of the 75 RTUs installed in the SCADA project mentioned above, some were located in areas that had no grid connection nearby. The feasibility study I conducted in these locations showed that using solar panels was cheaper in the long run than being grid-connected. The costs of the construction work, electrical and cable work, and the price of the electricity were considered for the grid-connected ones, while the battery and maintenance costs were considered for the solar ones.

Software

I mainly used two software during this project: Solar Simulations: System Advisor Model (SAM) and Solar Simulations: PVPLANNER as they provided all the needed tools for this simple job.

Not all off-grid RTUs were identical, some had different power consumptions than others, consequently, the design varied. That being said, they all had the following components:

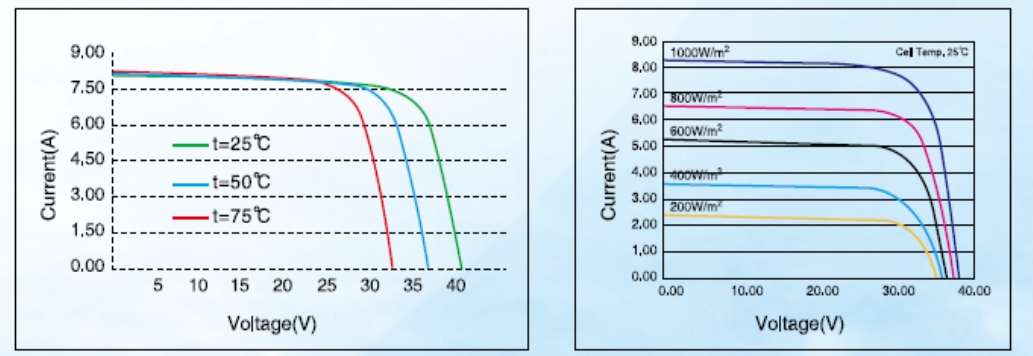

Solar panels

The solar panels were made of mono-crystalline, 230W, with wide operating temperature (-40 to 85 C) which made them suitable for the environment and the job required.

Img3: Solar panels electrical characteristics

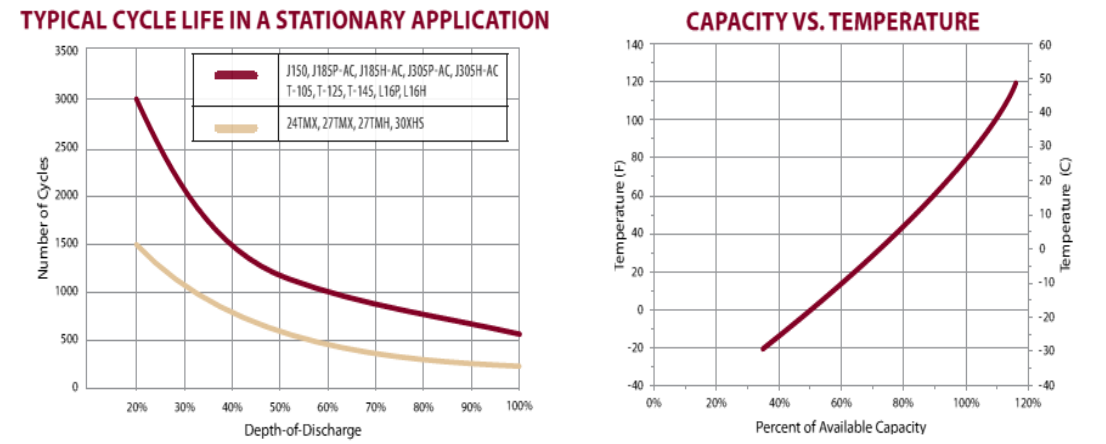

Batteries

The battery type was flooded/wet lead-acid batteries, providing two days of autonomy, and an optimal lifetime for 5 years, providing 2.2kwh at 100-hr rate.

Img4: Batteries characteristics

Img5: The batteries that were used

Solar Controller

A controller provided efficient charging as well as the warning and safety functions.

Inverters

AC/DC inverters were used to power up the panel by DC.

Accessories

The panels were also equipped with thermostats/fans that reported the temperature in realtime and sent it back to the SCADA control system. The reason was simple: to keep an eye on the temperature inside the electric panels, as a rule of thumb, every 10C degrees increase in the temperature would reduce the battery life in half (or double the battery reaction). A month of operation @35C was equal to two months @25C, so it was important to keep an eye on it to maximize the batteries lifespan.

Conclusion

The project was a success. I designed and installed an off-grid solar system for some of the RTUs in the Industrial Automation SCADA System project, which was more cost-effective and reliable than the grid connection in some locations. The solar panels powered all the equipment in the electrical panels, including the wireless system, efficiently and reliably.

Note: The comment section is powered by Cactus/Matrix. If you use the official Matrix server, you are good to go. However, if you use your personal Matrix server, make sure to log in with the first button and use your own client. This is because my CSP only allows Cactus/Matrix domains to connect from this site, and most likely, your profile picture will be broken!